Elevating Wet Area Construction: Knauf AQUAPANEL® Cement Board Indoor for Housebuilders

When it comes to constructing wet indoor areas, housebuilders face a unique set of challenges. Dampness is the principal cause of structural damage, and the materials used in these environments must meet stringent requirements. They need to resist water, chemicals, and mould while maintaining dimensional stability and durability. Knauf AQUAPANEL Cement Board Indoor is an ideal solution for housebuilders, offering high performance in wet and humid environments.

Designing and building in spaces constantly exposed to water and humidity requires materials that resist degradation and maintain structural integrity over time. Traditional construction materials like gypsum boards or wood often struggle in these environments. Problems such as swelling, warping and mould growth not only affect the building’s durability but can also pose significant health risks.

Commercial settings such as swimming pools can worsen these challenges due to their large-scale exposure to water, humidity and, in certain circumstances, chlorine. Similarly, residential bathrooms with power showers require materials that can handle high levels of moisture without frequent repairs. Addressing these issues while remaining compliant with industry standards is critical for ensuring well-functioning facilities.

Why Choose Knauf AQUAPANEL Cement Board Indoor?

Knauf AQUAPANEL Cement Board Indoor is a robust, high-performance tile backer board designed specifically for wet indoor areas. Manufactured from inorganic materials, it is unaffected by water and resistant to mould, ensuring long-lasting durability. Whether it’s bathrooms, kitchens, wet rooms, or even steam saunas, this system is engineered to withstand the most challenging conditions, including exposure to chlorine and salt.

But the benefits don’t stop there. AQUAPANEL Indoor is also lightweight compared to some cement boards, weighing just 11kg/m2, making it easier to handle and install. Its score-and-snap cutting method eliminates the need for specialist cutting tools and as the board doesn’t need to be pre drilled it saves time on installation too.

Meeting NHBC Standards with Confidence

Housebuilders must adhere to strict industry standards, particularly when it comes to wet area construction. The updated NHBC Technical Guidance 9.2/06 emphasises the importance of robust substrates for tiling in bath and shower enclosures, wet rooms, and bathroom pods. AQUAPANEL Cement Board Indoor is fully compliant with these guidelines, ensuring peace of mind for housebuilders and homeowners alike.

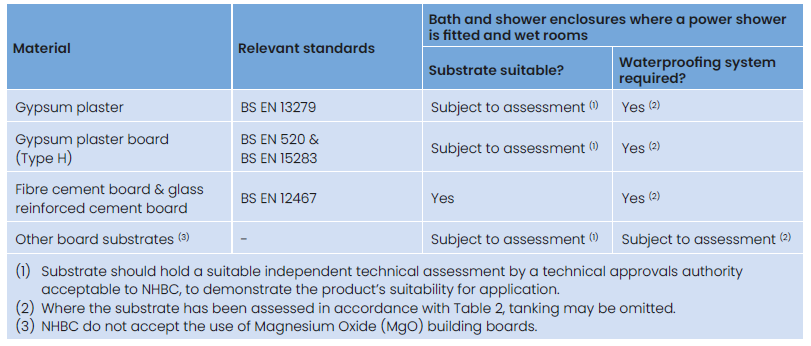

Table 1 from NHBC Technical Guidance – 9.2/06, fourth issue (November 2024)

The NHBC have stipulated higher performing substrates should be used in bath and shower enclosures where a power shower* is fitted and wet rooms, with compliant substrates, such as fibre cement boards and glass reinforced cement boards needing to conform with BS EN 12467. AQUAPANEL Cement Board Indoor meets these requirements, making it NHBC compliant for these wet area projects.

Versatile Finishing Options

AQUAPANEL Cement Board Indoor offers flexibility in design, with a variety of finishing options available. For tiled finishes, the system can support tiles up to 120kg/m2 with specific build-up applying for tile weights above 50kg/m2. For areas where tiles aren’t being applied, housebuilders can choose between two skim coating options:

Knauf Ready-Mixed Interior Skim: This option improves sustainability by reducing water usage and dust creation on site.

Knauf AQUAPANEL Joint Filler and Skim Coating – White: A powdered cement-based filling material used in conjunction with AQUAPANEL reinforcing mesh.

Special Applications: Behind Wood-Burning Stoves

AQUAPANEL Cement Board Indoor is not just for wet areas. It is also ideal as a tile substrate behind wood-burning stoves, as it can withstand radiating temperatures up to 200 degrees celcius. Its A1 non-combustible rating ensures safety, while its resistance to warping, shrinking, or expanding makes it a reliable choice for heat-resistant surface coatings and finishes.

The Complete System: Accessories for Seamless Integration

To ensure optimal performance, Knauf offers a range of accessories designed to work seamlessly with AQUAPANEL Cement Board Indoor and the AQUAPANEL finishing products mentioned earlier:

AQUAPANEL® Maxi Screws: For fixing boards onto timber or metal frameworks.

AQUAPANEL® Joint Adhesive: For bonding individual panels in wall applications, prior to tiles being applied

AQUAPANEL® Joint Tape: Used in conjunction with Knauf AQUAPANEL® Joint Filler and Skim Coating – White for reinforcing joints as part of the AQUAPANEL® Interior system.

Proven Performance: One Goodmayes, East London

Knauf AQUAPANEL® Cement Board Indoor has already proven its capabilities in high-profile projects like One Goodmayes in East London, which comprised of 573 studio, one and two bedroom apartments.

AQUAPANEL’s ability to be water, moisture and vapour resistant made it the ideal choice for wet areas such as bathrooms.

Elevating Construction Projects

For housebuilders committed to excellence, Knauf AQUAPANEL Cement Board Indoor is the solution for wet area construction. Its impressive durability, streamlined installation, and compliance with industry standards make it the ideal choice for projects where performance and efficiency are paramount.

Available nationally from CCF branches across the UK, Knauf AQUAPANEL Cement Board Indoor is ready to elevate your construction projects. Contact your local branch or Knauf for assistance at any stage of the design or installation process.

*A power shower is defined as incorporating a pump to boost the water flow rate (>12litres/min)